Just like every other task, running a machine is also

full of challenges and issues. One of the issues is leakage, which is faced

when the fluids enclosed in the machine part get leakage from the surface and

enter the outside environment. Leakage generally occurs from the two joining

surfaces of the machine or from the rotating parts like a shaft, rotor,

agitator, mixer, etc. this problem often results in disturbance and also causes

loss of the products. In some industries like petroleum, biochemical, pharmaceuticals,

the fluids can be toxic to people and are not supposed to enter the outside

environment. To overcome or prevent this problem, mechanical seals and gaskets

are used to create a strong seal that encloses the fluids in the system. We all

know that machines come in varying sizes and designs. Sometimes, the leakage

surfaces are not regular i.e. have some irregularities but they can still be

sealed, and if you ask how the answer would be- with the help of a gasket. It

allows the two surfaces to rotate or joined without letting the fluids leak.

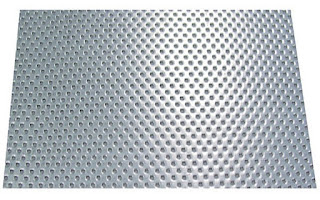

Gaskets are made up of sheets and different sheets of various materials like sheet rubber gasket material are used for their production.

Buy a gasket that can create a

long-lasting seal

The efficiency of the gasket greatly depends on the

machine conditions so it is very important to observe them. Conditions include

the speed, temperature, moisture, chemical nature, of the sealing surface. If

you are looking to buy a gasket for your machine then you should make sure to

observe all these conditions. To buy the gaskets and to get assistance in

choosing the best one for you, you need to click the link and visit the

website of American Seal and Packing to get their best products and services.